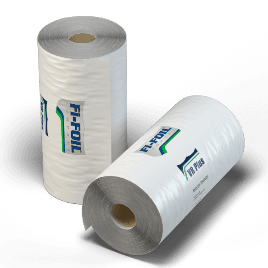

PREMIUM REFLECTIVE INSULATION

MANUFACTURER AND SUPPLIER

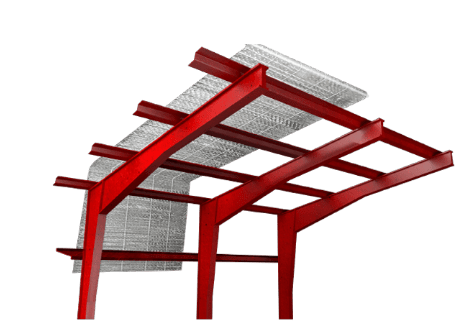

As a leading insulation manufacturer and supplier, we have pioneered the building industry with innovative reflective, radiant barrier, and specialty barrier solutions. We focus on advancing sustainable building practices, enhancing energy efficiency, and promoting environmental stewardship with a wide range of quality products that improve the resilience of buildings.

OUR COMMITMENT TO

SUSTAINABILITY AND INNOVATION

FI-FOIL® is at the forefront of integrating sustainable practices with reflective insulation and radiant barrier technology. Our relentless pursuit of eco-friendly solutions and advanced research leads the way in energy-efficient and environmentally responsible insulation.

THE FI-FOIL KNOWLEDGE BASE

As a leading insulation manufacturer and supplier, we have pioneered the building industry with forward-thinking reflective, radiant barrier and specialty insulation solutions. We focus on advancing sustainable building practices, enhancing energy efficiency and ensuring environmental stewardship across all our product ranges.

EXPERIENCE THE FI-FOIL ADVANTAGE

Where commitment to excellence is not just in our products but in every aspect of our customer journey. From the moment you engage with us, we offer personalized, expert consultation, ensuring that your needs are met with precision and professionalism. Our dedicated team provides support at every phase, from product selection, installation, and post-installation service. Our goal is to help you choose the right insulation and ensure a smooth installation to keep your projects on-time and on-budget. With FI-FOIL, you’re not just acquiring superior reflective insulation solutions; you’re gaining a reliable partner dedicated to enhancing the efficiency, comfort, and sustainability of your projects. Welcome to an experience where extraordinary service is at the heart of all we do.

EXPLORE OUR RANGE OF SPECIALIZED INSULATION PRODUCTS

We offer diverse specialized insulation products, each designed to meet specific needs in various applications. Our product lineup provides optimal solutions across various settings, from radiant barriers to SCIF barriers and Class A Facing insulation.