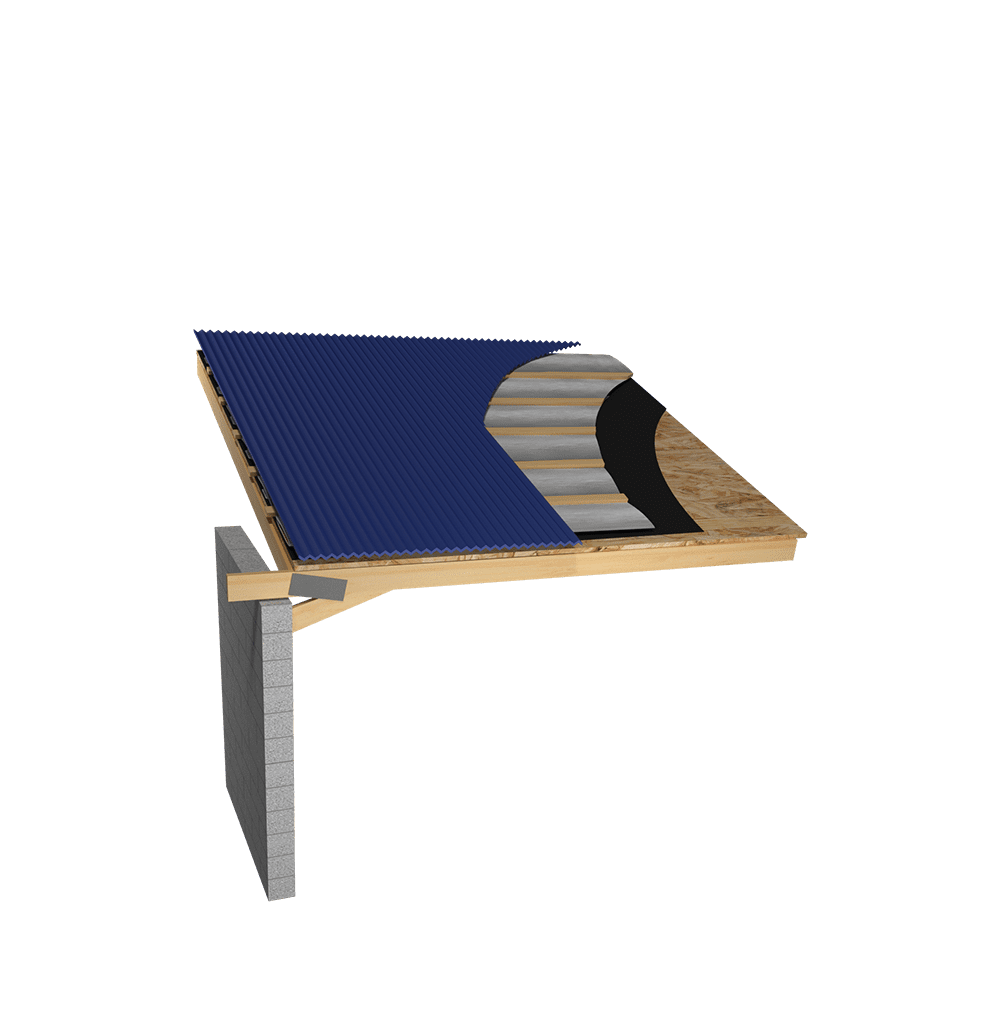

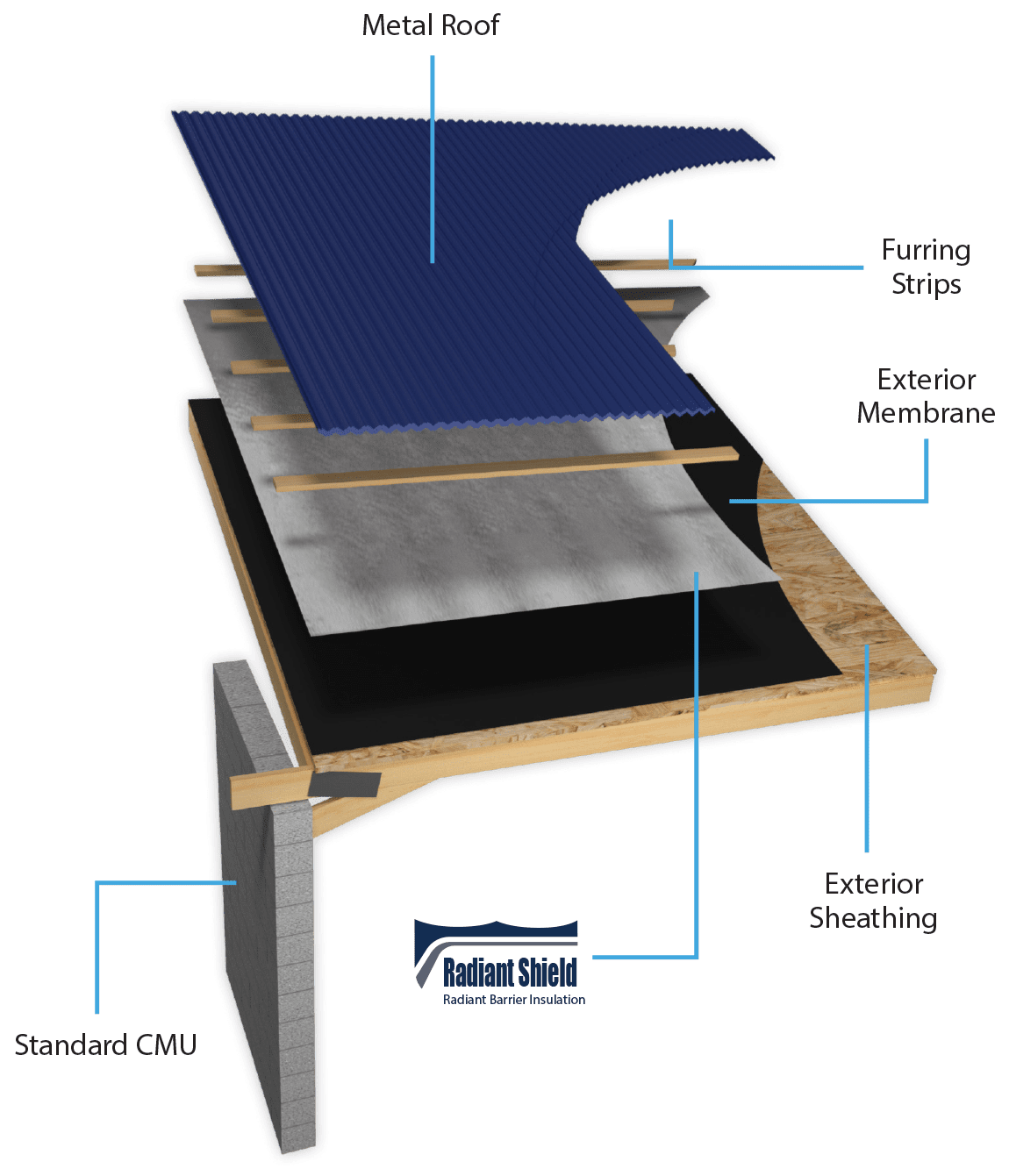

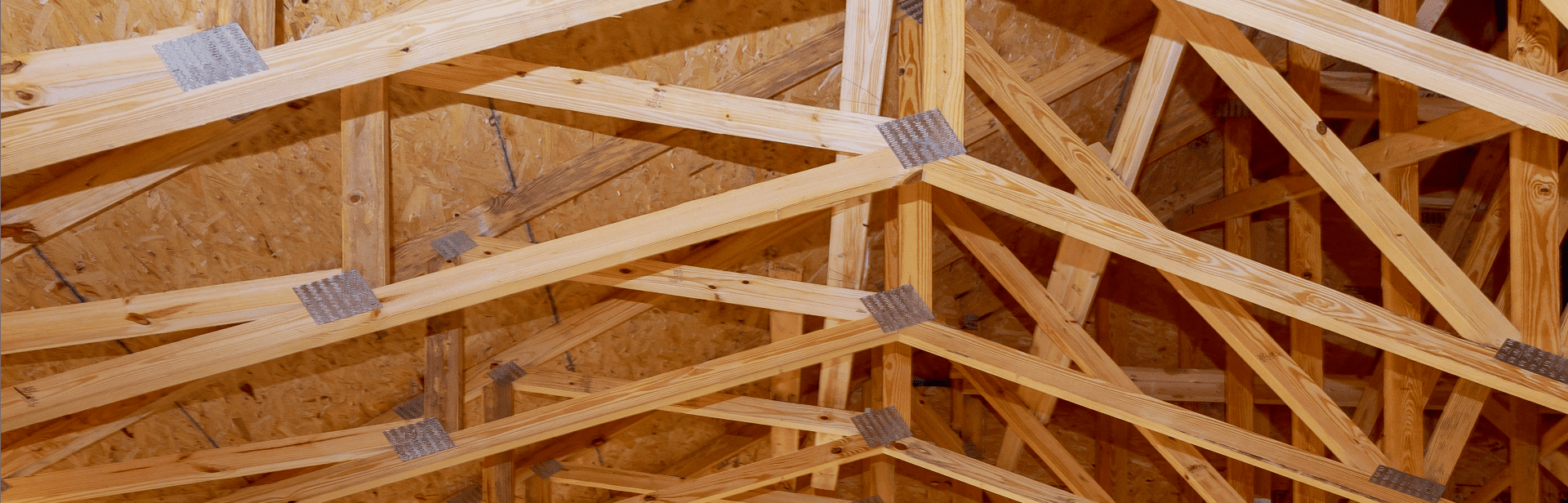

Radiant Shield™ is a heavy-duty two-sided aluminum foil radiant barrier. Designed and reinforced with woven polyethylene, it provides industrial strength for any radiant barrier application. The product is also designed with perforations to allow vapor transmission for protection against heat and humidity.

Features & Benefits That Make the Difference

- Premium Grade Radiant Barrier

- Designed with Two (2) Layers of Aluminum Foil Laminated to a Layer of Woven Polyethylene

- Industrial Strength, Tear Resistant

- Perforated to Allow Vapor Transmission

- Contains Antioxidants that Reduce the Impact of UV Light and Oxidation

- Low-e Surfaces Reduce 95% of Radiant Heat Transfer

- Ideal for Wood & Metal Roofs

- 25.5″ 48″ and 51″ Widths

- Perforated to Allow Vapor Transmission

- 500 sq. ft. Rolls

- Class A Flammability Rating

- Supports Sustainable Design Goals

- National Network of Insulation Distributors and Contractors

- Reduces Attic Temperatures in the Summer

- Reduces Heat Loss in the Winter

- Improves HVAC Ducts and System Efficiency

- Increases Energy Efficiency to Lower Cooling and Heating Costs

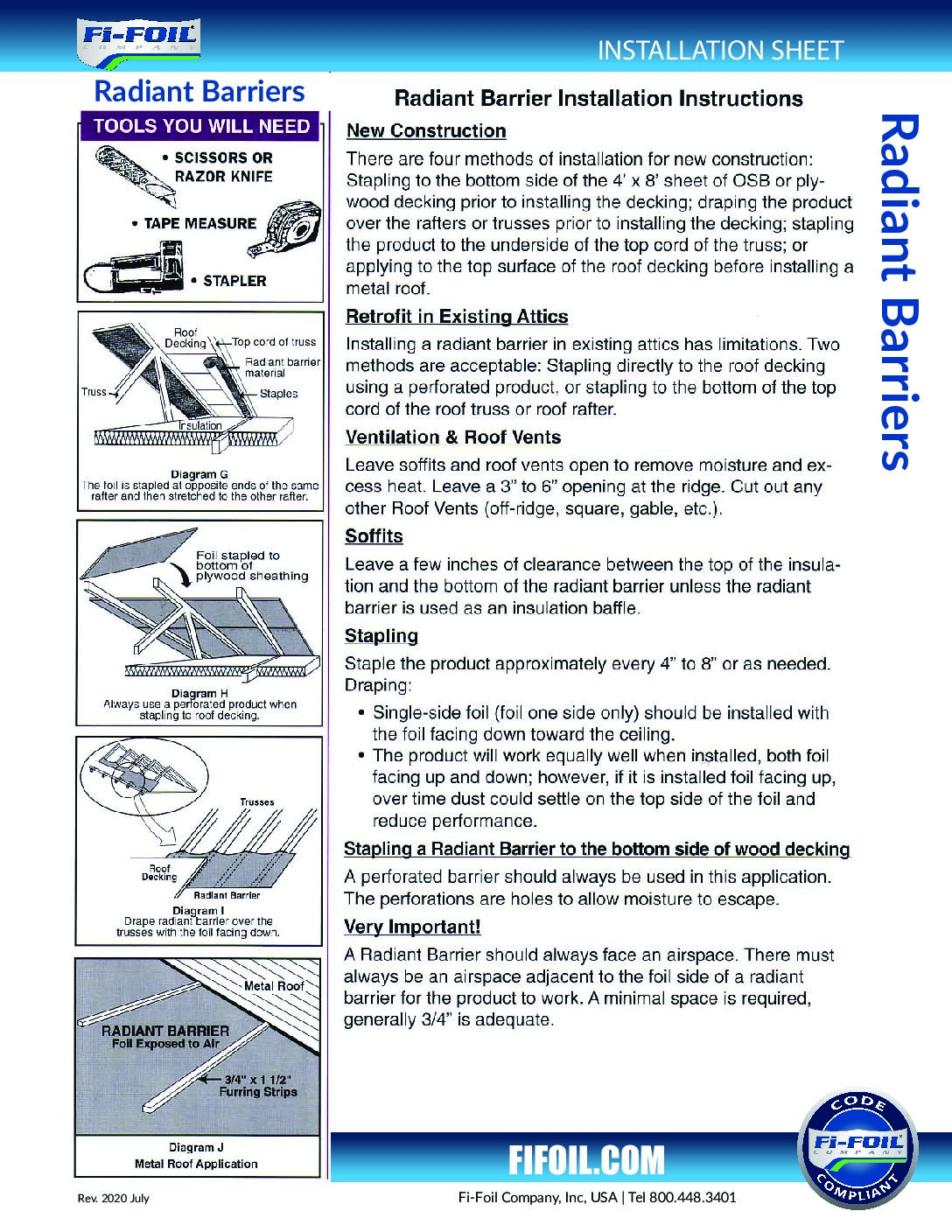

- Easy to Install

- Price Competitive

- Considerably Less Expensive than Spray Foam

- In Summer, Lowers Temperatures to Improve Comfort in Areas Not Typically Air Conditioned such as Garages, Porches & Lanais

- Stands up against heat and humidity

| Width of Roll | 25.5″ | 48″ | 51″ | |

| Weight | 14 lbs | 14 lbs | 14 lbs | |

| Lineal Footage | 236′ | 125′ | 118′ | |

| Coverage | 500 sq. ft. | 500 sq. ft. | 500 sq. ft. |

| Test Method | Description | Results |

|---|---|---|

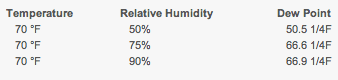

| ASTM E-96 | Water Vapor Permeance | 13.9 (Perforated) <0.01 (Non-Perforated) |

| ASTM E-84-94 | Flammability Flame Spread Rating | < 25 |

| Smoke Developed Rating | < 50 | |

| National Fire Protection Association Rating | Class 1 / Class A | |

| ASTM C-1371 | Emissivity | 0.03 – 0.04 (Non-Perforated) |

| ASTM C-1338 | Mold & Mildew | Does Not Promote Growth (Non-Perforated) |

| ASTM D-2261 | Tear Resistance – MD | 27.6 pounds (Non-Perforated) |

| Tear Resistance – CD | 26.1 pounds (Non-Perforated) | |

| ASTM C-1313 | Pliability | Pass (Non-Perforated) |

| Bleeding / Delamination | None (Non-Perforated) | |

| ASTM D-3310 | Corrosivity | Pass (Non-Perforated) |

Meeting Industry Standards: Code and Compliance Information for Radiant Shield™

- ASTM C-1313, STANDARD SPECIFICATION FOR RADIANT BARRIERS

- FLORIDA BUILDING CODE

- INTERNATIONAL BUILDING CODE

- DOE Supported Performance and Results for Radiant Barriers (RB)

- Florida Solar Energy Center Supported Performance and Results for RBs

- Meets International Building Codes (IBC)

- Meets International Residential Codes (IRC)

- Meets International Energy Conservation Codes (IECC)

- Meets Florida Building Codes (FBC)

- Meets Florida Residential Codes (FRC)

- Meets Florida Energy Conservation Codes (FECC)

- Third-Party Verified Code Compliance, IAPMO ER 266

- Meets ASTM C 1313, Sheet Radiant Barriers

TECHNICAL DOCUMENTS

FREQUENTLY ASKED QUESTIONS

Request Product Support

Please don’t hesitate to reach out for inquiries, project consultations, or more information about FI-FOIL® reflective insulation system solutions. Our team of experts is dedicated to providing personalized assistance and technical expertise to meet your specific needs. Please note that the more completely the fields below are filled out, the more accurate your response will be.

A TRUSTED LEADER FOR REFLECTIVE INSULATION TECHNOLOGIES

PROVIDING YOU WITH SERVICE, INTEGRITY AND INNOVATION

We manufacture, market, and distribute high-performance reflective insulation technology and radiant barriers. Our products are sustainable and improve building performance and comfort all year round. Our reflective insulation technology is one of the fastest-growing technologies in the world and we want you to grow with us.