By: Bill Lippy

Originally published: 01/02/2017 in Metal Construction News

A look at the impact of low-emittance materials on air spaces to improve building performance

Choosing the right insulation system is critical to saving money, meeting strict codes and improving facility appearance. With so many factors and choices available to building professionals today, it can be hard to decide the best building envelope solutions that are also smart budget decisions. Here’s a look at why radiant barriers and reflective insulation are cost-effective ways to improve the building envelope.

The Steel Factor

Steel is an excellent conductor that stores and radiates unwanted heat in the summer. And, in the winter, condensation can result on roof decks, steel beams or purlins causing energy costs, comfort and productivity to be compromised. By combining traditional insulation with a radiant barrier (an insulation with low-emittance (low-E) surfaces) radiant heat gain in the summer and heat loss in the winter can be minimized to improve energy efficiency, savings and a more comfortable workspace for owners and facility teams. Radiant Barriers and Reflective Insulation The American Society of Testing and Materials (ASTM) defines a radiant barrier and/or reflective insulation as a reflective, low-E surface with an emittance of less than 10 percent.

Emittance measurements of all building materials range from zero (0.0)-no radiant heat transfer-to one (1.0)-equal to a black surface with complete radiant heat transfer. Common materials such as steel, wood, masonry and fiberglass insulation have high-emittance surfaces that typically range from 0.82 to 0.90 and therefore have high rates of radiant heat transfer.

Radiant barrier and reflective insulation materials have much lower emittance values, ranging from 0.03 to 0.06 and thus radiate significantly less energy from the surface, making these a simple and effective solution to improve building performance and reduce facility energy costs. This reduces the carbon footprint for a more sustainable solution for the building envelope.

Other Benefits

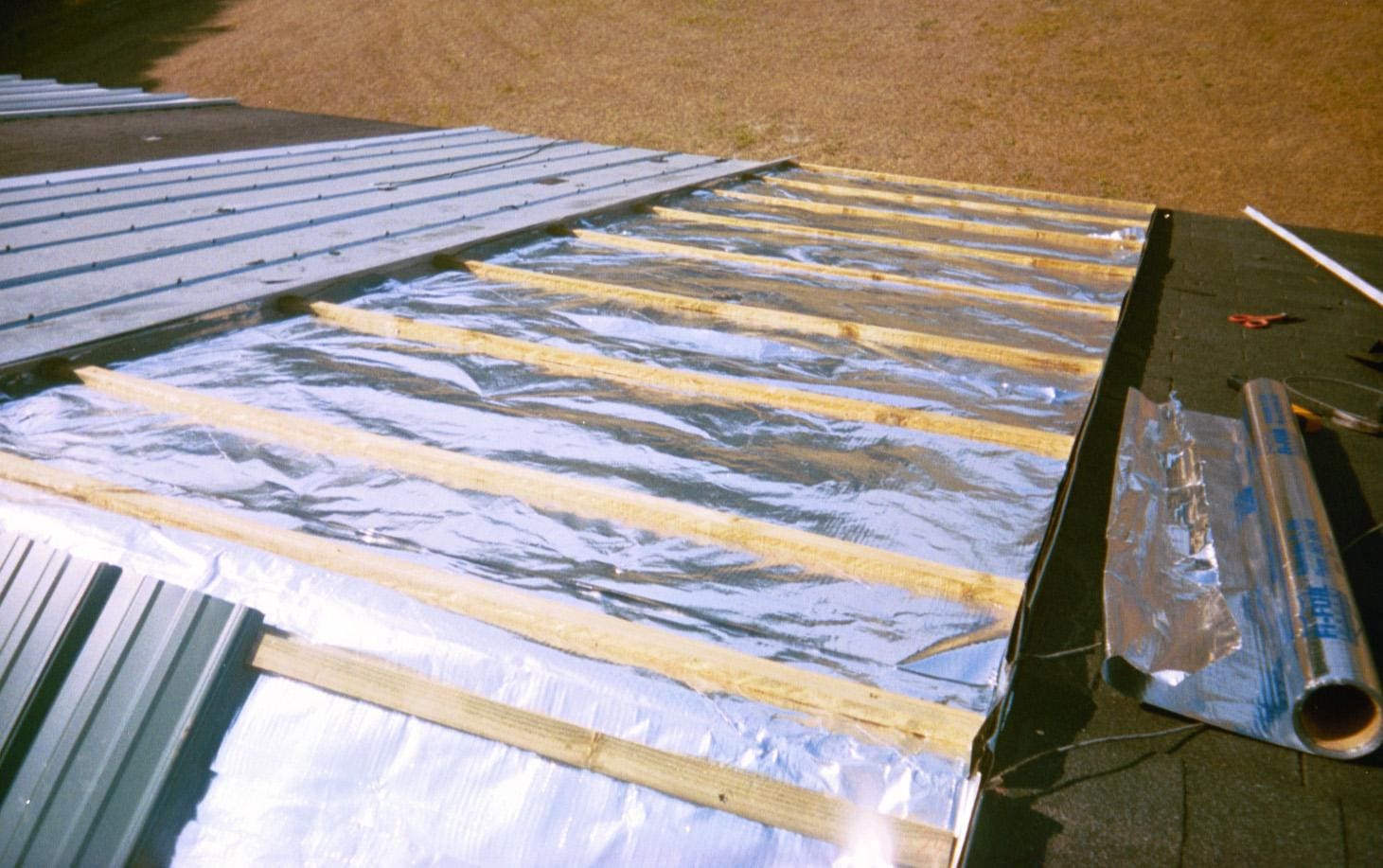

A radiant barrier insulation system utilizes ventilation to improve performance, especially in summer conditions. A good example is a ventilated cavity below a metal roof application-a common application in residential re-roofing projects. A reflective insulation system utilizes the same low-E technology. The difference is a reflective insulation system is installed to enclose a building cavity, which utilizes and improves the performance of the air within the cavity leading to a higher building performance. An example of this in a metal building would be a reflective insulation system installed on the bottom of metal purlins to enclose a 6- to 8-inch purlin-and-beam section. Using this approach creates a continuous insulation layer, helping industry professionals meet the code, in less time, with less material.

ASTM Tested Results and Savings

Radiant barriers typically incorporate ventilation, therefore are not measured in terms of R-value. Instead, the industry uses software for calculating building performance, including a measure of reduction in ceiling heat flux and reduced load on HVAC ducts if installed in attic spaces with radiant barriers. Reflective insulation systems on the other hand are installed over cavities, enclosing the air spaces, so R-values can be determined using ASTM test methods, calculated using ASTM methodology or from tables in the ASHRAE Handbook of Fundamentals.

Studies have proven the performance of radiant barriers in metal building construction. And, the Florida Solar Energy Center, Cocoa, Fla., has performed side-by-side tests using a base case roof with dark shingles compared with a metal roof radiant barrier system. The average mid-attic temperature reduction for the roof with the radiant barrier was 19 degrees in the summer and the average ceiling heat flux change was reduced by 43 percent. The metal roof radiant barrier system cooling savings was 11 percent compared to the dark shingle roof system.

Consider the Gain and Appearance

Reflective insulation is versatile and works well with all types of metal building framing. More facility managers are choosing reflective insulation systems to fix damaged or falling pre-existing insulation. Cost effective and remarkably easy to install, one select system on the market adds R-12 to R-16 and can be back-loaded with existing or other insulation for additional thermal performance. Reducing the effects of radiant heat transfer, this system provides some air sealing and completes the building with a clean, finished look.

Bill Lippy is a past president of the Reflective Insulation Manufacturers Association International (RIMA), and president and CEO of Fi-Foil Co. in Auburndale, Fla. To learn more, visit www.fifoil.com or call (800) 448-3401.