Reflective insulation combines a radiant barrier’s effectiveness with traditional insulation’s thermal performance when used in enclosed airspaces in wall or ceiling applications.

Single and multi layer reflective insulation is designed with low-emittance (Low-e) surfaces and expander technology that separates each layer to create two or more reflective air spaces within the wall or ceiling cavity. Low-e foil layer(s) insulate enclosed air spaces to reduce convection and conduction.

Importantly, Low-e layers also reduce radiation—the third mode of radiant heat transfer not commonly addressed by mass insulation. In residential and commercial buildings, adequate insulation enables walls and ceilings to withstand the stresses of heat infiltration and humidity (in summer) and exfiltration (in winter) to maximize energy efficiency and performance.

Reflective Insulation – HY-Fi® Hybrid Insulation System

FI-FOIL® Reflective Insulation Products

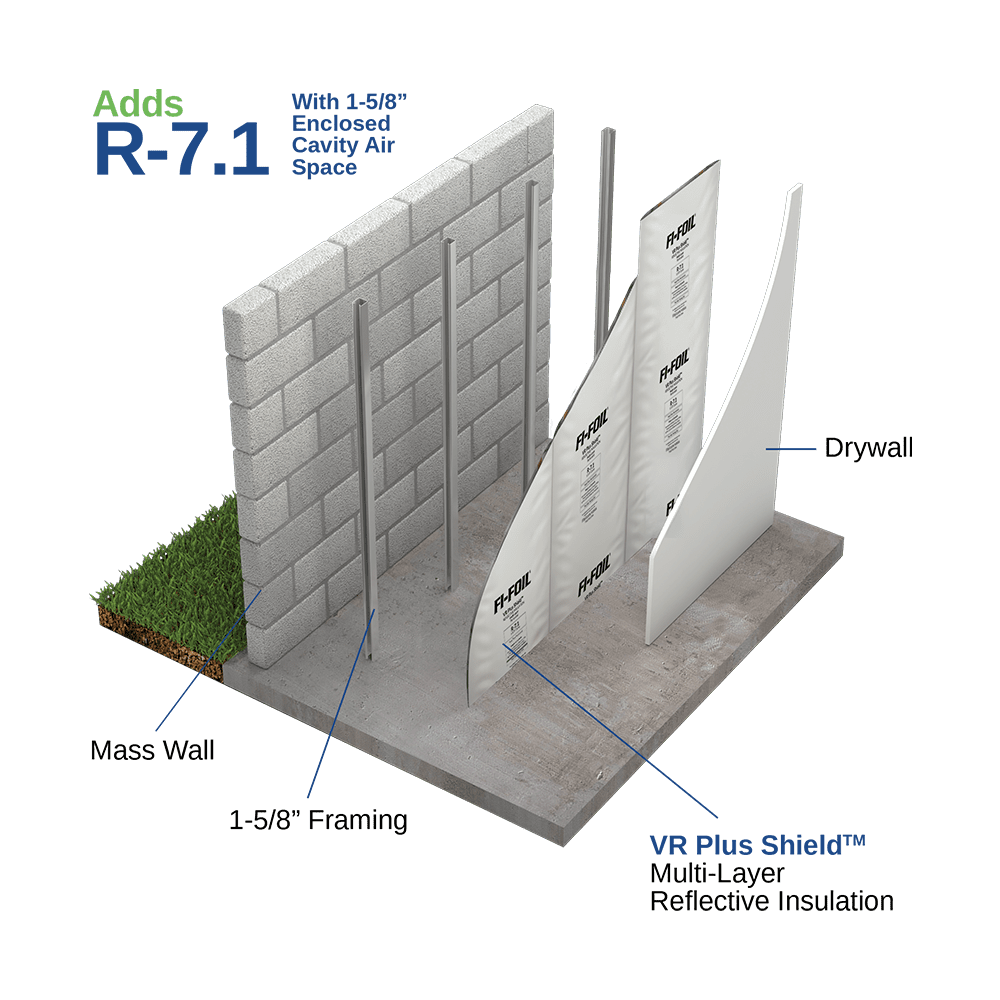

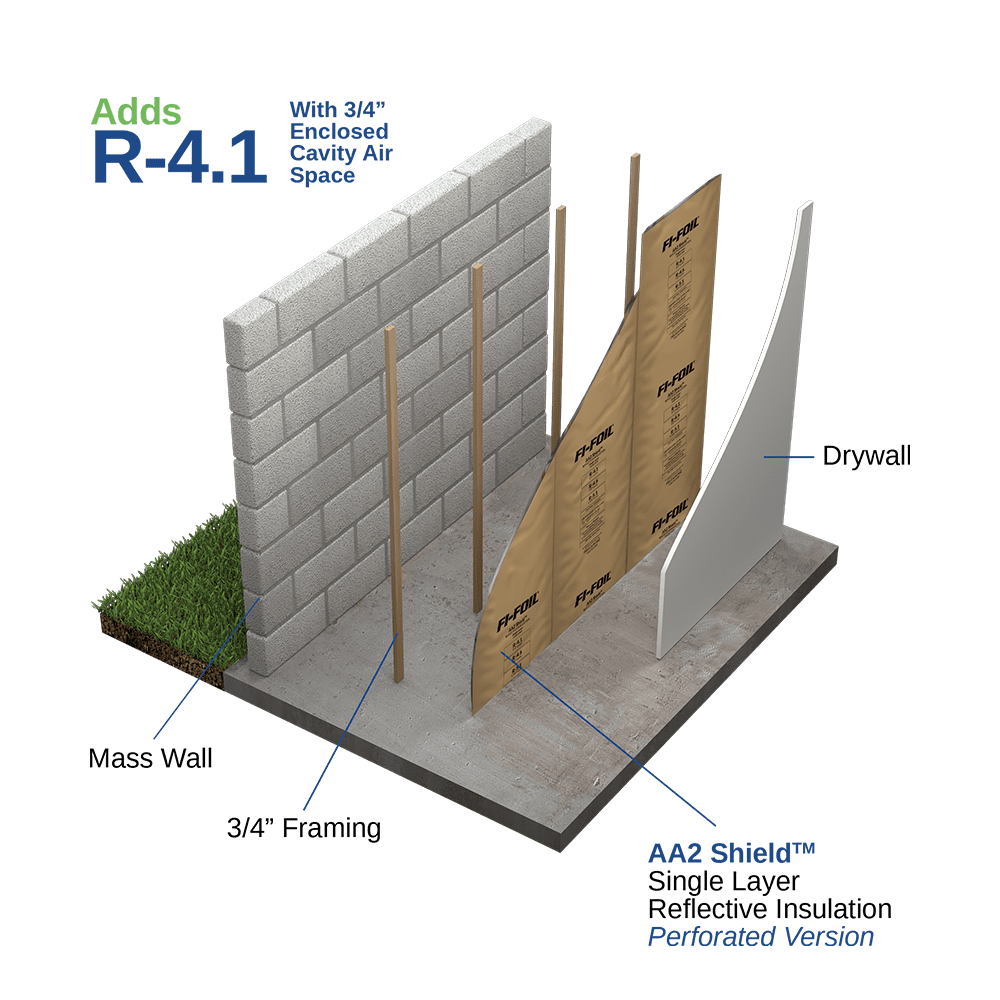

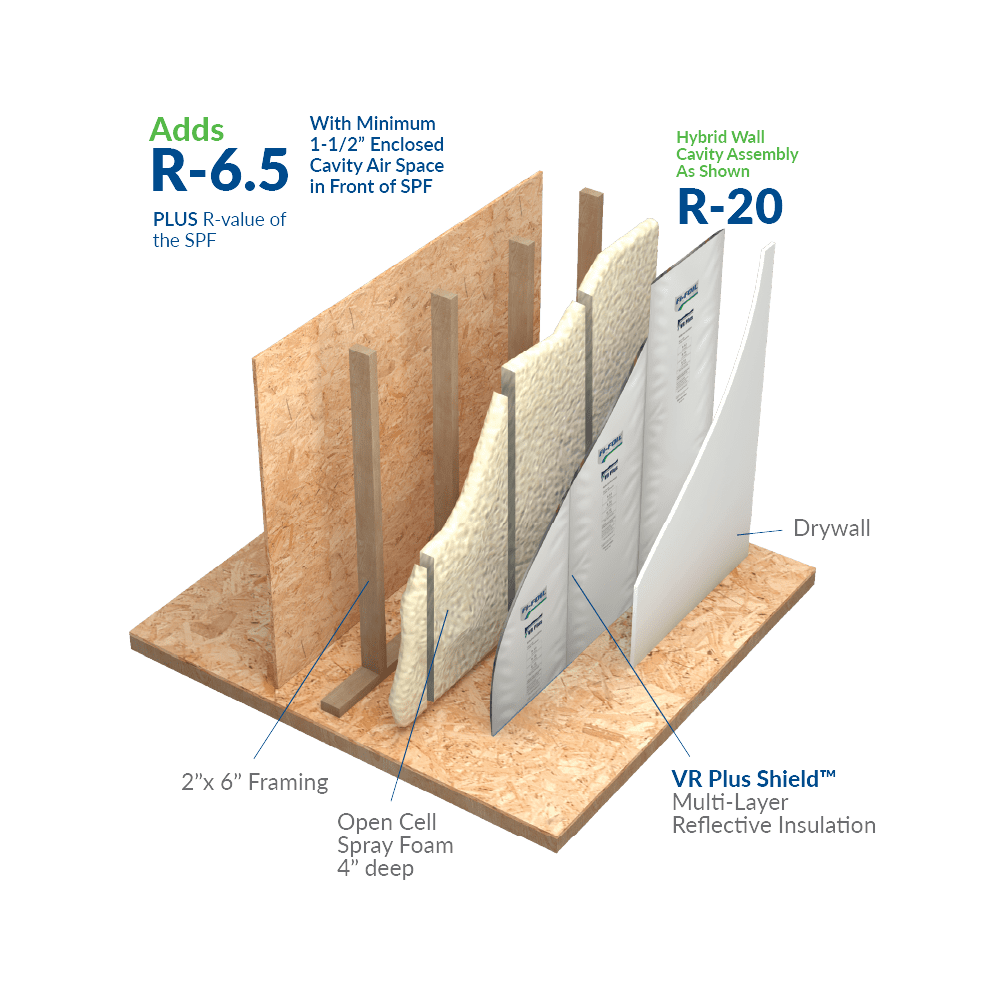

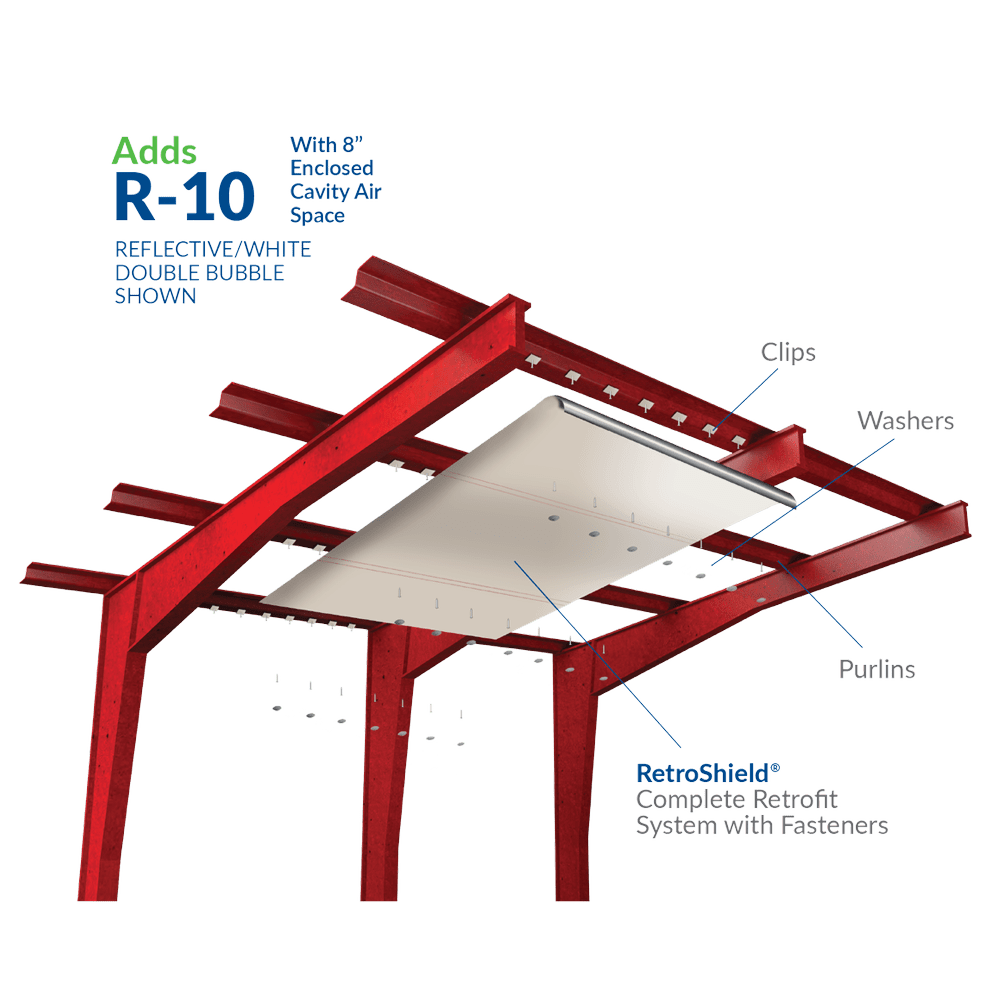

FI-FOIL® reflective radiant insulation adds R-value with as little as 3/4″ with one layer to a minimum of 1-1/2″ of enclosed cavity air space to gain R-4.0 to R-7.0 for wall and ceiling assemblies. Reflective insulation works well alone or together as a system with other insulation materials and can provide architects and builders the potential to increase livable and workable spaces in buildings.

FI-FOIL® offers a range of aluminum reflective insulation products. The Vr Plus Shield™ Hybrid Insulation System combines a radiant barrier with an additional layer with fiberglass scrim for conductive heat resistance on frame walls and ceilings often used by custom builders to lower Home Energy Rating Scores (HERS).

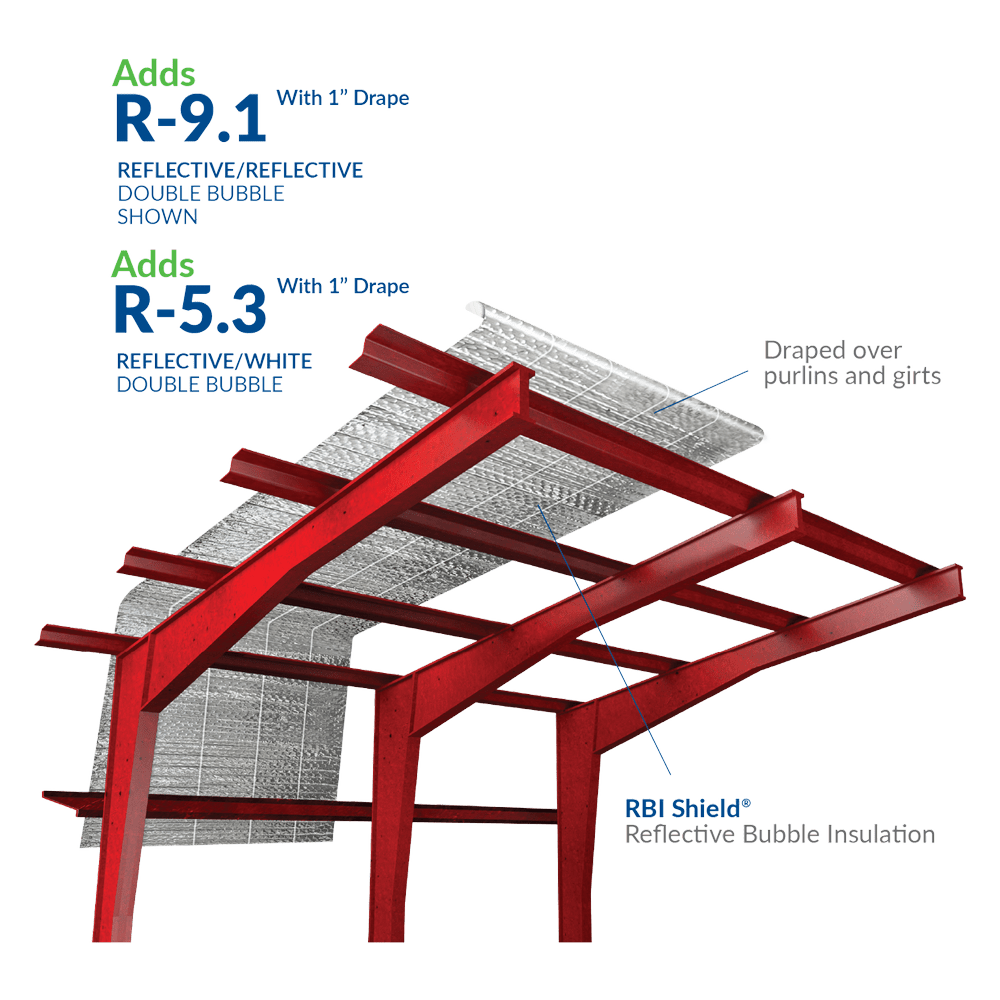

Other options include VR Plus Shield™ multi-layer radiant insulation for high performance on masonry walls, M-Shield® paperless radiant insulation for moisture-sensitive projects, AA2 Shield™ and RBI Shield™, a multipurpose reflective bubble insulation often used in crawl-space installations.

Subscribe to FI-FOIL® Product Updates

Get In Touch!

Have A Project In Mind? Let’s Talk.