Opt for a Multi-Layered Insulation Technology Solution

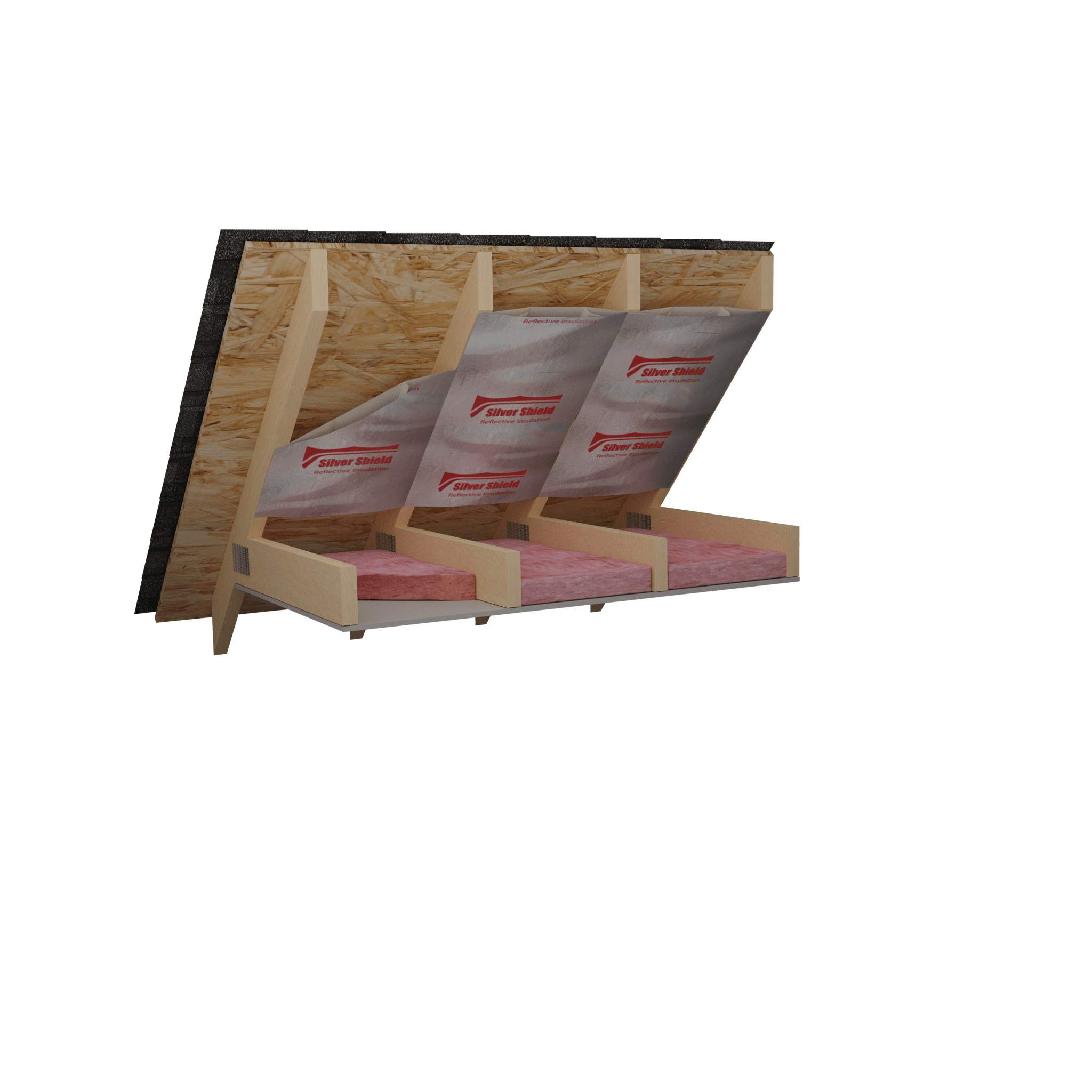

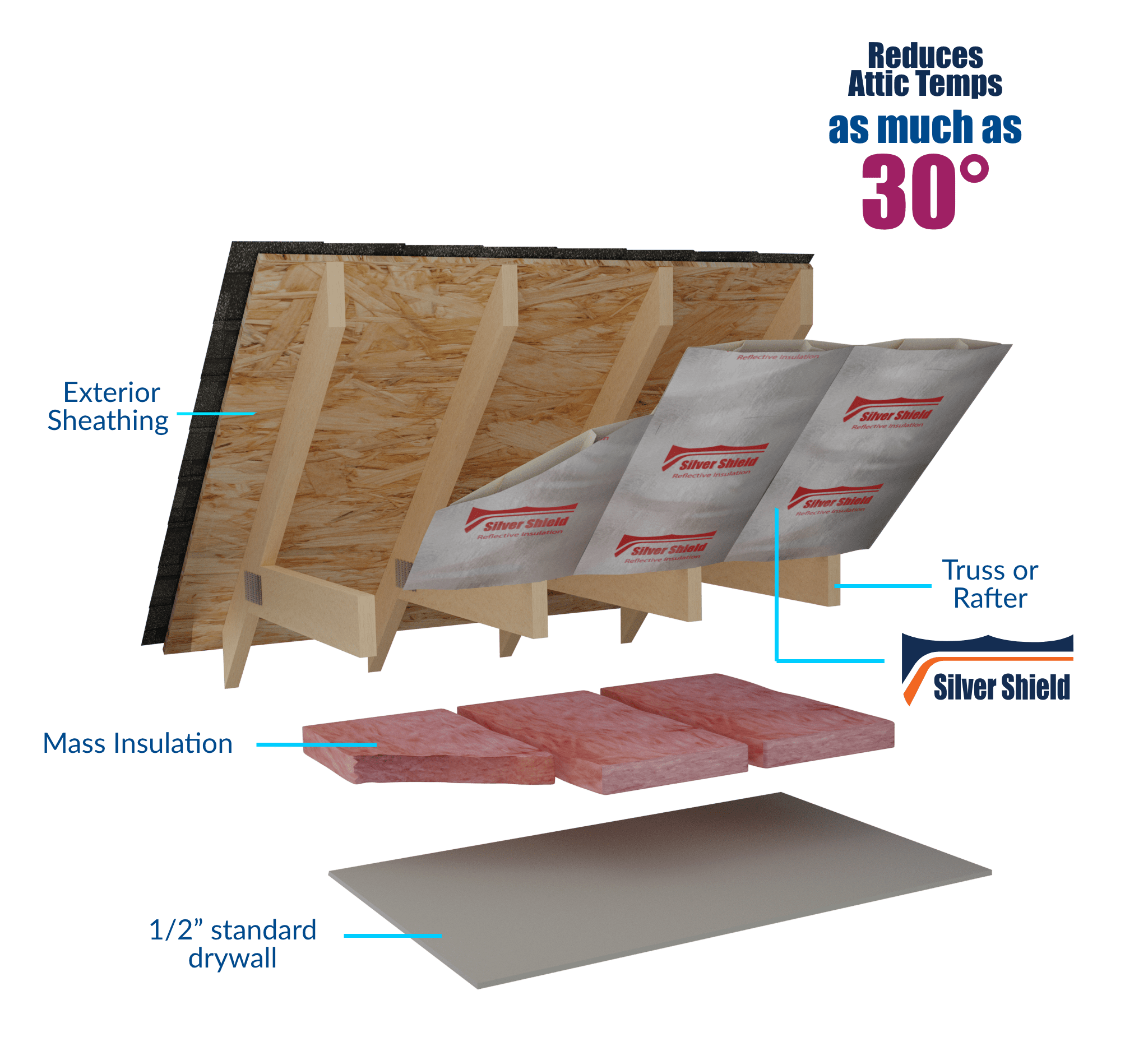

Boost R-Value with our Radiant Barrier. Silver Shield™ is an insulating product composed of multiple layers of low emittance (Low-e) materials designed to reduce radiant heat transfer significantly. The inside layer is a metalized polymer. The outside layer is reinforced aluminum foil kraft paper bonded with a fire retardant adhesive. The layers expand when installed to form a reflective air space to provide enhanced thermal performance and protect the low emittance surface from the performance-reducing effects of dust accumulation. Since metalized and foil-based aluminum products have a near zero water vapor permeance, Silver Shield™ is perforated to allow water vapor transmission, for better protection against heat and humidity.

Multifaceted Advantages of Silver Shield™

- Multi-Layer, Low-e Highest Performing Radiant Barrier

- Reflects 97% of Radiant Heat at the Roof

- Third-Party Verified Code Compliance, IAPMO ER 291

- Outer Layer of Kraft Paper Reinforced with Aluminum

- Inner Layer of Metalized Polymer

- Fi-Foil Expander Technology Separates Layers

- Layers Expand to Form Two (2) Reflective Air Spaces

- Strong and Tear Resistant

- Perforated to Allow Vapor Transmission

- Reflective layers are Designed to be Protected from Dust Accumulation

- Perforated to Allow Vapor Transmission

- Low-e Surfaces Reduce Radiant Heat Transfer

- Quick Installation with Staple Tab

- 16″ 24″ and 30″ Widths

- 500 sq. ft. Rolls

- 20-Year Transferrable Warranty on Material & Labor

- Verified Recycled Content >20%

- Class A Flammability Rating

- Supports Sustainability Goals

- National Network of Insulation Distributors and Contractors

- Third-Party Verified Code Compliance, IAPMO ER 291

- Keeps Homes Cooler in the Summer and Warmer in the Winter

- Proven Performance Reduces Attic Temperatures up to 30°F in the Summer

- Reduces Heat Loss in the Winter

- Provides R value to Increase thermal performance of Attic Insulation

- Increases Comfort of Living and Work Spaces in All Seasons

- Improves HVAC Ducts and System Performance up to 50%

- Reduces Cooling Costs up to 16% in the Summer

- Reduces Utility Peak Load Demand

- Easy to Install

- Price Competitive

- Considerably Less Expensive than Spray Foam

- 30% Reduction in Heat Flow to Conditioned Space vs- Liquid Applied Low-e Coating

- 17% Reduction in Heat Flow to Conditioned Space vs- Deck Applied Radiant Barrier

- 4x More Effective than Adding Additional Insulation (during Peak loads)

- Meets Attic Radiant Barrier Requirements for Energy Star Homes

- Lowers HERS® and Other Energy Rating Indexes (ERI)

- More Comfortable Buildings

- Better Energy Efficiency

- Supports Sustainable Design Goals

- Protection in Hot and Humid Climates

- Foil Insulation acts like an Attic Heat Shield

| Furring/Stud Spacing | 16″ O.C | 24 ” O.C | 30″ O.C | |

| Width Expanded | 17.5″ | 25.5″ | 31.5″ | |

| Diameter | 8″ | 10″ | 6″ | |

| Lineal Footage | 375′ | 250′ | 100′ | |

| Coverage | 500 sq. ft. | 500 sq. ft. | 250 sq. ft | |

| Weight | 26 lbs | 22 lbs | 10 lbs |

| Test Method | Description | Results |

|---|---|---|

| ASTM E-96 | Water Vapor Permeance Hi-Perm | 5.00 perms |

| ASTM E-84 | Flammability Flame Spread Rating | 0 |

| ASTM E-84 | Smoke Development Rating | 0 |

| ASTM E-84 | Interior Wall & Ceiling Finish Classification | Class A |

| ASTM C-1371 | Thermal Emittance 1st Layer MET PVC Metal Side | 0.04 |

| ASTM C-1371 | 2nd Layer Foil Laminate | 0.03 |

| ASTM STP 1116 | R-values for a Reflective Air Space Heat Flow Up at 45º (Enclosed 3/4” air space) | R-2.0 |

| Heat Flow Down at 45º (Enclosed 3/4” air space) | R-3.3 | |

| Heat Flow Horizontal (single low-e surface) | R-1.7 | |

| Heat Flow Horizontal (multiple low-e surfaces with an enclosed 3/4” air space) | R-4.6 | |

| ASTM D-3310 | Corrosivity | Pass |

| ASTM C-1224/Section 9 Adhesive Performance | Bleeding | None |

| Delamination | None | |

| Pliability | No signs of cracking or delamination | |

| ASTM D-2261 | Tongue Tear Test | MD 1.77 CD 2.32 |

| ASTM C-1338 | Mold & Mildew | Pass |

Meeting the Mark: Code and Compliances

- Meets or exceeds ASTM C1313.

- Meets International Building, Residential and Energy Codes.

- Meets Florida Building, Residential and Energy Conversation Codes.

- IAPMO Evaluation Report number 0291.

- DOE Supported Performance and Results for Radiant Barriers (RB).

- Florida Solar Energy Center Supported Performance and Results for RBs

- Meets International Building Codes (IBC)

- Meets International Residential Codes (IRC).

- Meets International Energy Conservation Codes (IECC).

- Meets Florida Building Codes (FBC).

- Meets Florida Residential Codes (FRC).

- Meets Florida Energy Conservation Codes (FECC)

TECHNICAL DOCUMENTS

Your Content Goes Here

FREQUENTLY ASKED QUESTIONS

Request Product Support

Please don’t hesitate to reach out for inquiries, project consultations, or more information about FI-FOIL® reflective insulation system solutions. Our team of experts is dedicated to providing personalized assistance and technical expertise to meet your specific needs. Please note that the more completely the fields below are filled out, the more accurate your response will be.

A TRUSTED LEADER FOR REFLECTIVE INSULATION TECHNOLOGIES

PROVIDING YOU WITH SERVICE, INTEGRITY AND INNOVATION

We manufacture, market, and distribute high-performance reflective insulation technology and radiant barriers. Our products are sustainable and improve building performance and comfort all year round. Our reflective insulation technology is one of the fastest-growing technologies in the world and we want you to grow with us.