The Industry Leading Zero Mold Reflective Insulation for Masonry Walls

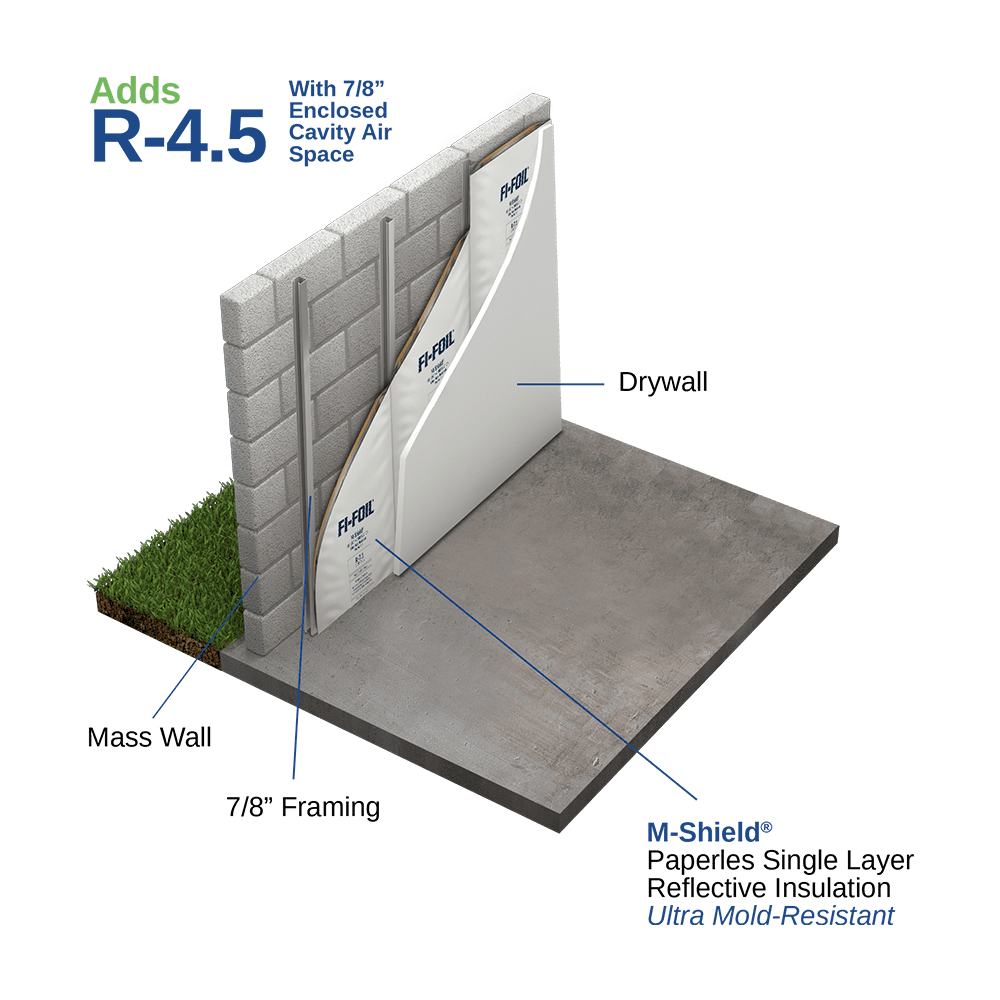

An advanced insulation technology used on furred-out Masonry walls, M-Shield® is designed to resist mold growth by combining a synthetic polymer facing on premium grade aluminum foil. The synthetic polymers contain no cellulose and, therefore, reduce the risk of exposure to create safer, better air quality. When tested to ASTM standards, M-Shield® exhibited zero mold or mildew growth. It’s remarkably easy to install and created to get you more R-value for less, saving labor and material.

Blocks heat transfer up to 97% and includes an industry-leading 10-year transferable warranty. In more humid climates, M-Shield® is a smart choice to insulate all your masonry buildings.

How It Works

M-Shield® has two layers. The inside layer is aluminum foil. The outer layer is a synthetic polymer material and the product is designed with small perforations to allow vapor transmission for applications not requiring a vapor retarder.

Our technology uses expanders that separate the paper from the foil to create reflective air spaces. When installed on furring strips, 16″ or 24″ on-center, the air is trapped inside the cavity, and the reflective components improve the performance.

Since the reflective layers also reduce the sizes of the airspaces in the cavity, reflective insulation also reduces heat transfer by convection. The result is a more comfortable building and better energy efficiency.

Your Go-To Solution for Reflective Masonry Wall Insulation Features & Benefits

- Paperless Reflective Airspaces for Mold Sensitive Projects

- Two (2) Layer Reflective Airspaces

- Outer Layer of Synthetic Polymer Facing

- Inner Layer of Premium Grade Aluminum Foil

- FI-FOIL® Expander Technology Separates Outer Layer from Foil

- Low-e Surfaces Reduce Radiant Heat Transfer

- Quick Installation with Staple Tab

- Use with Wood Furring or Metal Framing

- 16″ or 24″ widths

- Perforated or Solid

- Lightweight 500 sq ft Rolls

- Blocks Heat Transfer up to 97%

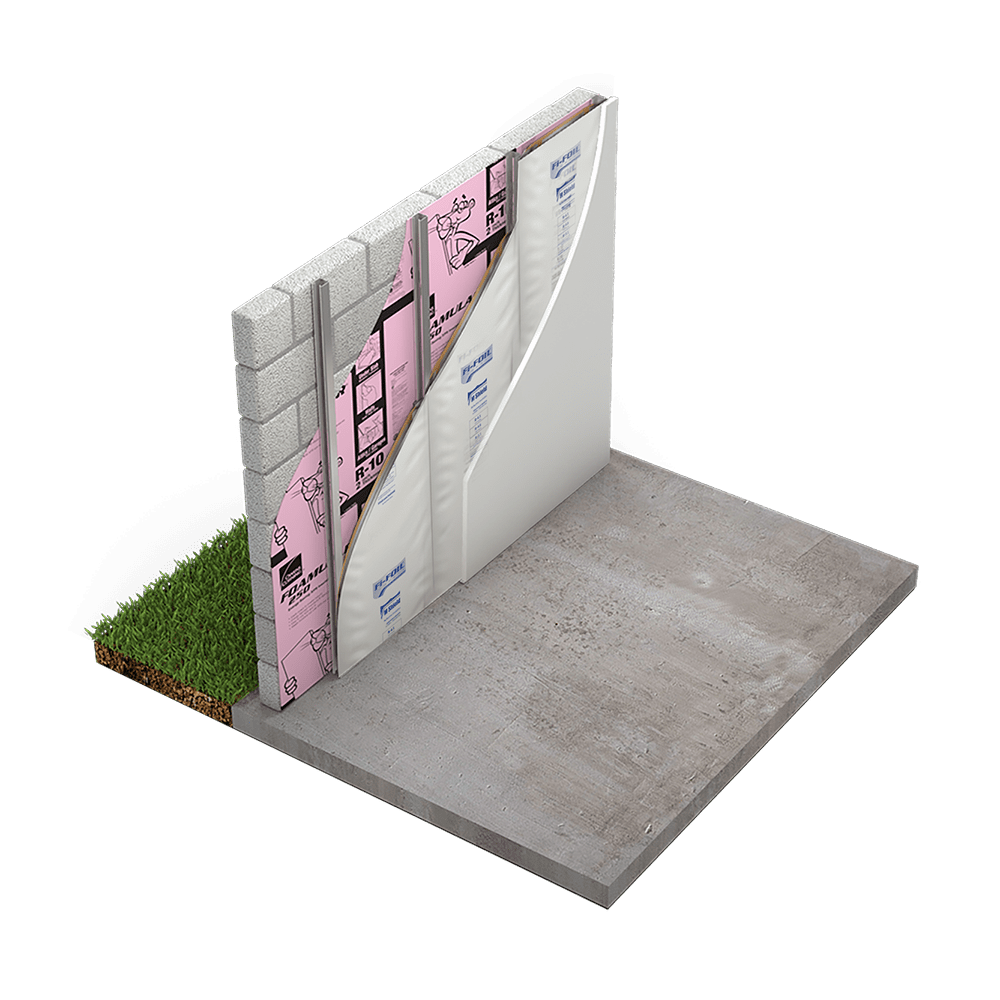

- Easily Combine with Other Mass Insulation as part of a Wall System

- Add up to R-5.1 with just 1-1/2″ Enclosed Air Space

- Zero Mold Growth

- Class A Flammability Rating

- Supports Sustainability Goals

- Add R-4.1 to R-4.5

- Improve Indoor Air Quality

- Lightweight 500 sq. ft. Rolls

- Easy to Handle, Installs Faster

- Save Labor

- Save Warehouse Space

- Save on Material & Shipping

- High Performance and Compact

- Provides for More Living Area Square-Footage for Increased Marketability

- Lowest Cost per R-value of All Masonry Wall Insulation

- Low-e Reflective Surfaces Improve Performance of Enclosed Air Space

- Lowers HERS® and Other Energy Rating Indexes (ERI)

- More Comfortable Buildings

- Better Energy Efficiency

- 10-Year Warranty

- National Network of Insulation Distributors and Contractors

Meeting the Standards: M-Shields ASTM Certification and Zero Mold Growth

- Meets ASTM C-1224-03, Standard Specification of Reflective Insulation

- Meets National/Florida Building and Energy Code Requirements

- Meets International Building Codes (IBC)

- Meets International Residential Codes (IRC)

- Meets International Energy Conservation Codes (IECC)

- Meets Florida Building Codes (FBC)

- Meets Florida Residential Codes (FRC)

- Meets Florida Energy Conservation Codes (FECC)

- Third-Party Verified Code Compliance, IAPMO ER 291

TECHNICAL DOCUMENTS

Request Product Support

Please don’t hesitate to reach out for inquiries, project consultations, or more information about FI-FOIL® reflective insulation system solutions. Our team of experts is dedicated to providing personalized assistance and technical expertise to meet your specific needs. Please note that the more completely the fields below are filled out, the more accurate your response will be.

A TRUSTED LEADER FOR REFLECTIVE INSULATION TECHNOLOGIES

PROVIDING YOU WITH SERVICE, INTEGRITY AND INNOVATION

We manufacture, market, and distribute high-performance reflective insulation technology and radiant barriers. Our products are sustainable and improve building performance and comfort all year round. Our reflective insulation technology is one of the fastest-growing technologies in the world and we want you to grow with us.

![M-Shield with Masonry Wall on Hat Channel [PDF] M-Shield® with Masonry Wall on Hat Channel [PDF]](https://b3524466.smushcdn.com/3524466/wp-content/uploads/2024/02/M-Shield-with-Masonry-Wall-on-Hat-Channel-PDF-pdf.jpg?lossy=2&strip=1&webp=1)

![M-Shield with Masonry Wall on Metal Framing [PDF] M-Shield® with Masonry Wall on Metal Framing [PDF]](https://b3524466.smushcdn.com/3524466/wp-content/uploads/2024/02/M-Shield-with-Masonry-Wall-on-Metal-Framing-PDF-pdf.jpg?lossy=2&strip=1&webp=1)

![M-Shield with Masonry Wall on Wood Furring [PDF] M-Shield® with Masonry Wall on Wood Furring [PDF]](https://b3524466.smushcdn.com/3524466/wp-content/uploads/2024/02/M-Shield-with-Masonry-Wall-on-Wood-Furring-PDF-pdf.jpg?lossy=2&strip=1&webp=1)

![Masonry Wall with M-Shield or AA2 Shield And Continuous Flex Foam Board Insulation Masonry Wall with M-Shield® or M-Shield® and Continuous Flex Foam Board Insulation [PDF]](https://b3524466.smushcdn.com/3524466/wp-content/uploads/2024/02/Masonry-Wall-with-M-Shield-or-AA2-Vapor-Shield-And-Continuous-Flex-Foam-Board-Insulation-1-pdf.jpg?lossy=2&strip=1&webp=1)