Easy to Use Metal Building Insulation for Retrofit Applications

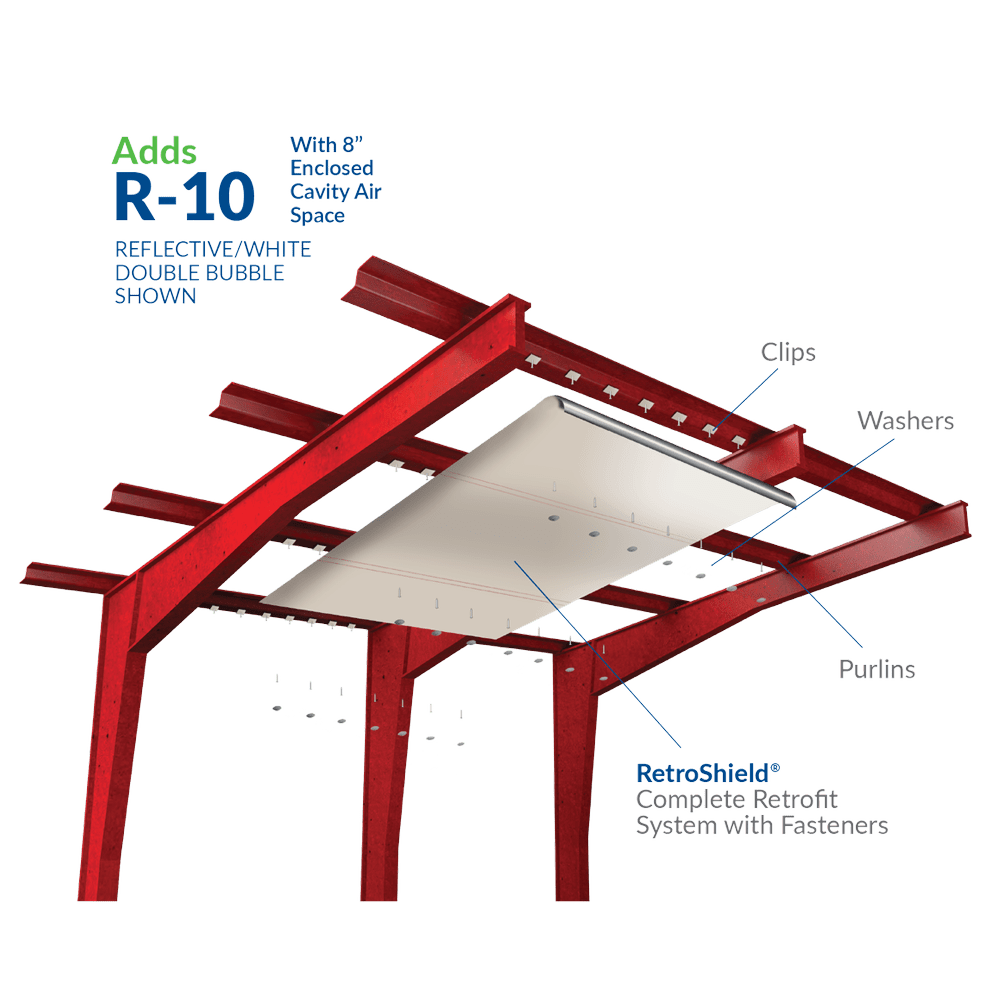

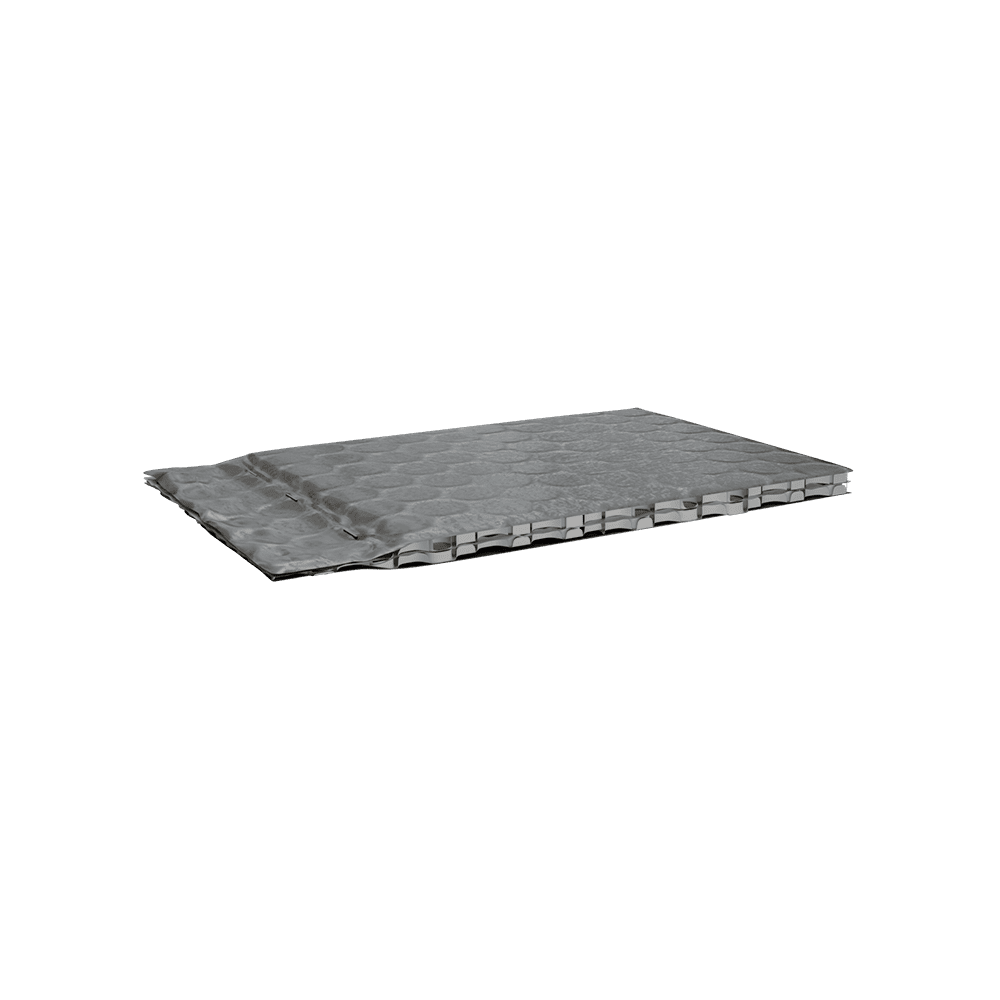

RetroShield® is a reflective insulation solution for metal building retrofits, uniquely designed for metal and steel building structures. This system redefines retrofit insulation for existing metal buildings, offering a fast, efficient installation process that stands out among other metal building retrofit insulation systems.

Effortless Installation, Exceptional Performance

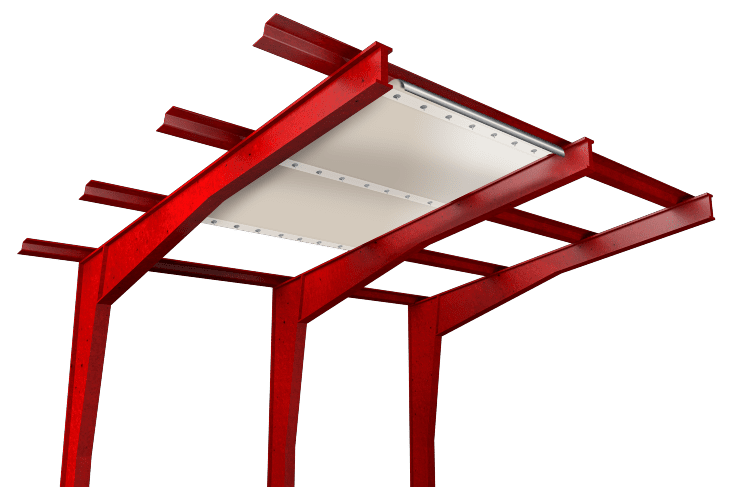

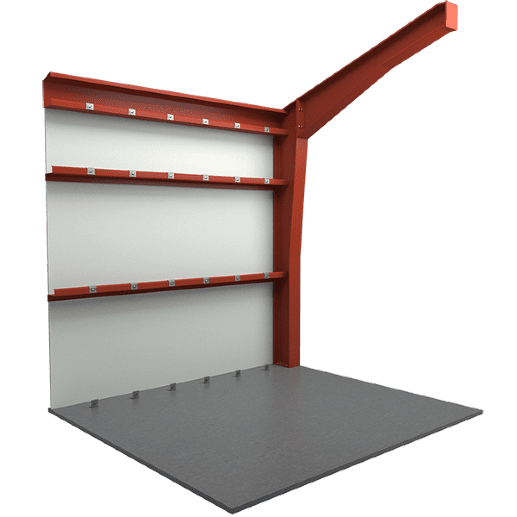

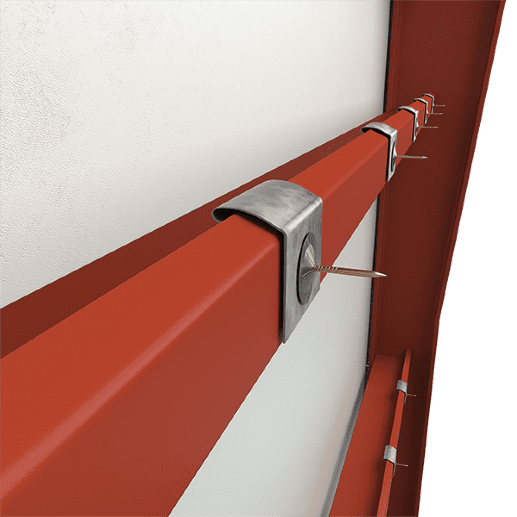

With our patented Clip & Pin technology, RetroShield® simplifies the retrofit metal building insulation process. This innovation eliminates the need for external supports, making it an ideal metal building insulation retrofit option that promises long-term stability and an aesthetically pleasing finish.

Superior Thermal Performance

RetroShield® retrofit insulation significantly enhances metal building roof and walls, reducing radiant heat transfer by 94%. This reflective insulation technology provides high reflectivity and low emissivity for superior thermal performance. The RetroShield® System offers continuous insulation and can be back-loaded with additional mass insulation for specific thermal performance or R-value requirements.

Features and Benefits of Retrofit Insulation

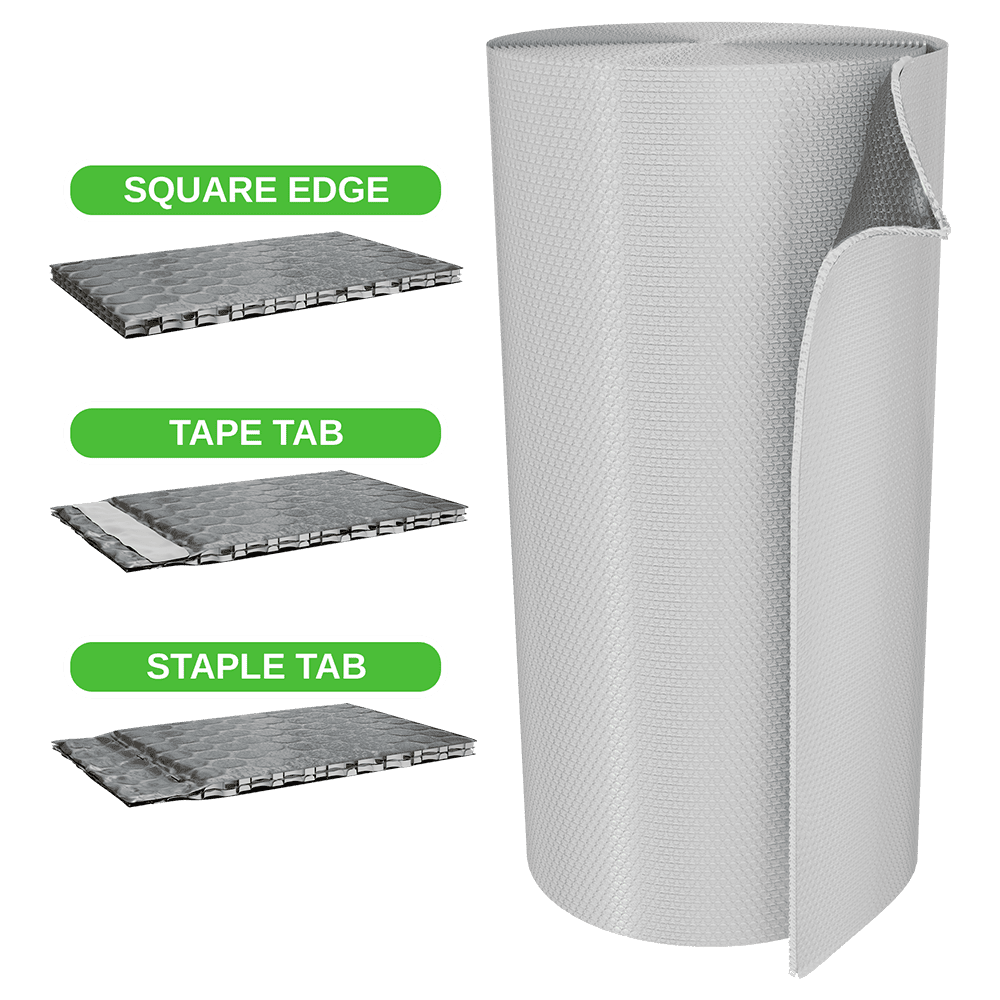

- 48″, 54″, 66″, and 72″ Widths Available

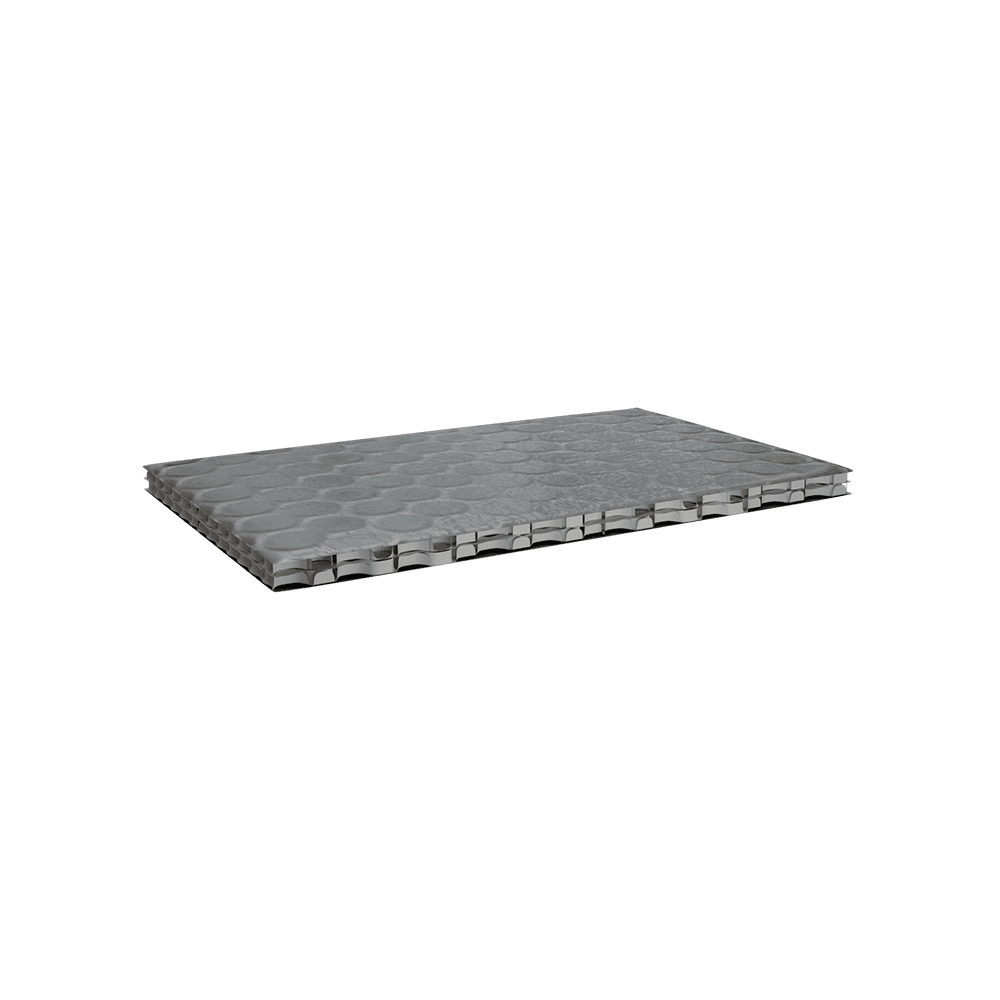

- Single or Double Bubble Versions Available

- Moisture-Resistant Material

- Contains Proprietary Blend of Strengthening & Color Stabilizing Compounds

- Contains Antioxidants that Reduce the Impact of UV Light and Oxidation

- Class A Flammability Rating, Reflective/Reflective option

- Integral Tap Tab Option to Seal Seams and Provide a Clean, Finished Look

- Installer-Friendly, No Itchy Fibers

- Less Expensive than Spray Foam

- Can be Used Alone or Back-Loaded with Mass Insulation in Cooler Climate Zones

- Reduces Condensation

- Adds Thermal Performance & Comfort, Year-Round

- Stops 95% of Radiant Heat Transfer

- Saves Energy to Reduce Operating Costs

- R&D Formulated With A Premium White Polymer Facing

- Doubles as An Attractive Ceiling

- Brightens the Workspace

- No Cracking, Peeling, Pitting, Chalking or Discoloration

- Best-In-Class Performance & Strength

- Cuts to Fit and Seal Easily Around Skylights, Existing Equipment or Other Fixtures

- Reflective Technology Keeps Buildings Cooler in the Summer, Warmer in the Winter to improve comfort with Less Load on HVAC Systems

- Protects Your Assets

- Lifetime Limited Warranty

- National Network of Distributors & Contractors

Product Compliances

- Meets or Exceeds ASTM C-1224-03 Standard Specification of Reflective Insulation

- Meets International Building, Residential and Energy Codes

- Meets Florida Building, Residential and Energy Conservation Codes

- IAPMO Evaluation Report 0291

TECHNICAL DOCUMENTS

IDEAL ADDITIONAL BUILDING APPLICATIONS FOR REFLECTIVE INSULATION

FREQUENTLY ASKED QUESTIONS

Request Product Support

Please don’t hesitate to reach out for inquiries, project consultations, or more information about FI-FOIL® reflective insulation system solutions. Our team of experts is dedicated to providing personalized assistance and technical expertise to meet your specific needs. Please note that the more completely the fields below are filled out, the more accurate your response will be.

A TRUSTED LEADER FOR REFLECTIVE INSULATION TECHNOLOGIES

PROVIDING YOU WITH SERVICE, INTEGRITY AND INNOVATION

We manufacture, market, and distribute high-performance reflective insulation technology and radiant barriers. Our products are sustainable and improve building performance and comfort all year round. Our reflective insulation technology is one of the fastest-growing technologies in the world and we want you to grow with us.

![FI-FOIL Metal Building Retrofit with RBI Shield Backfilled with Fiberglass Insulation FI-FOIL® Metal Building Retrofit with RetroShield® Backfilled with Fiberglass [PDF]](https://b3524466.smushcdn.com/3524466/wp-content/uploads/2024/03/FI-FOIL-Metal-Building-Retrofit-with-RBI-Shield-Backfilled-with-Fiberglass-Insulation-pdf.jpg?lossy=2&strip=1&webp=1)

![FI-FOIL Metal Building Retrofit with RBI-Shield Over Vinyl-Faced Batt FI-FOIL® Metal Building Retrofit with RetroShield® Over Vinyl-Faced Batt [PDF]](https://b3524466.smushcdn.com/3524466/wp-content/uploads/2024/03/FI-FOIL-Metal-Building-Retrofit-with-RBI-Shield-pdf.jpg?lossy=2&strip=1&webp=1)