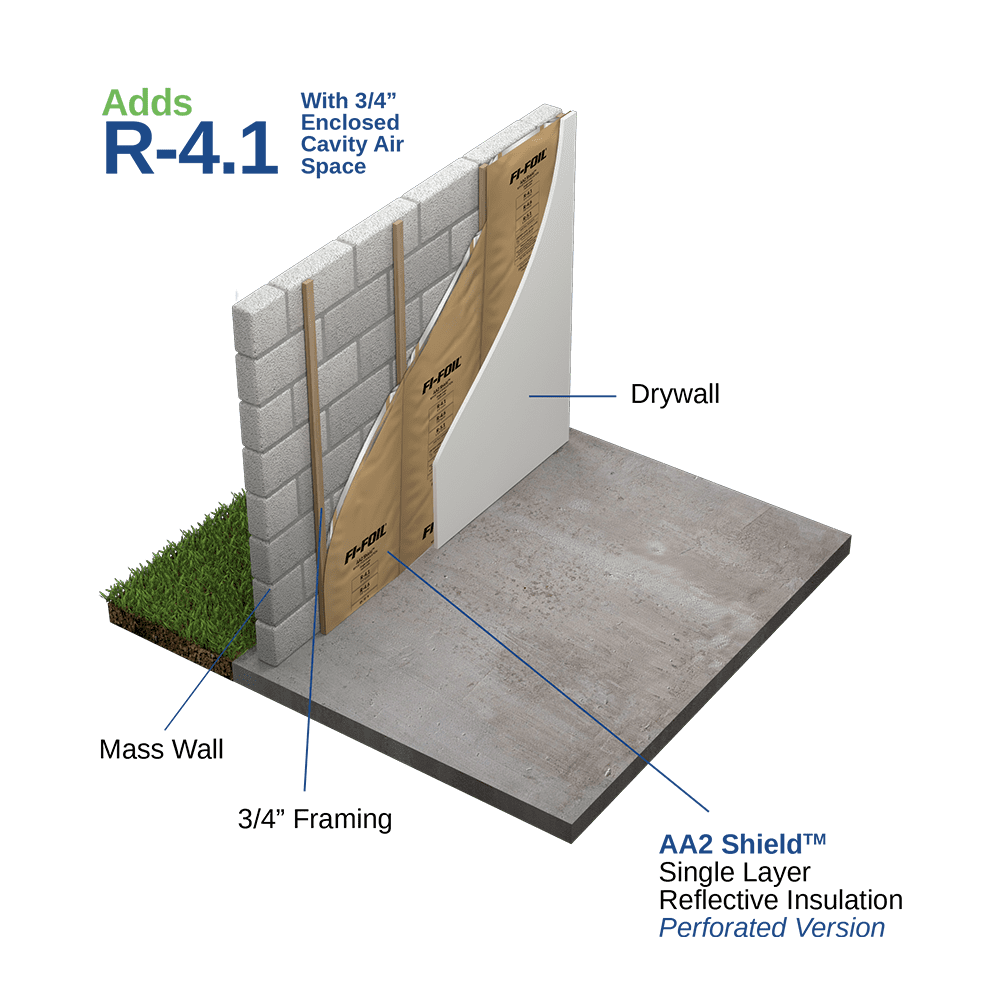

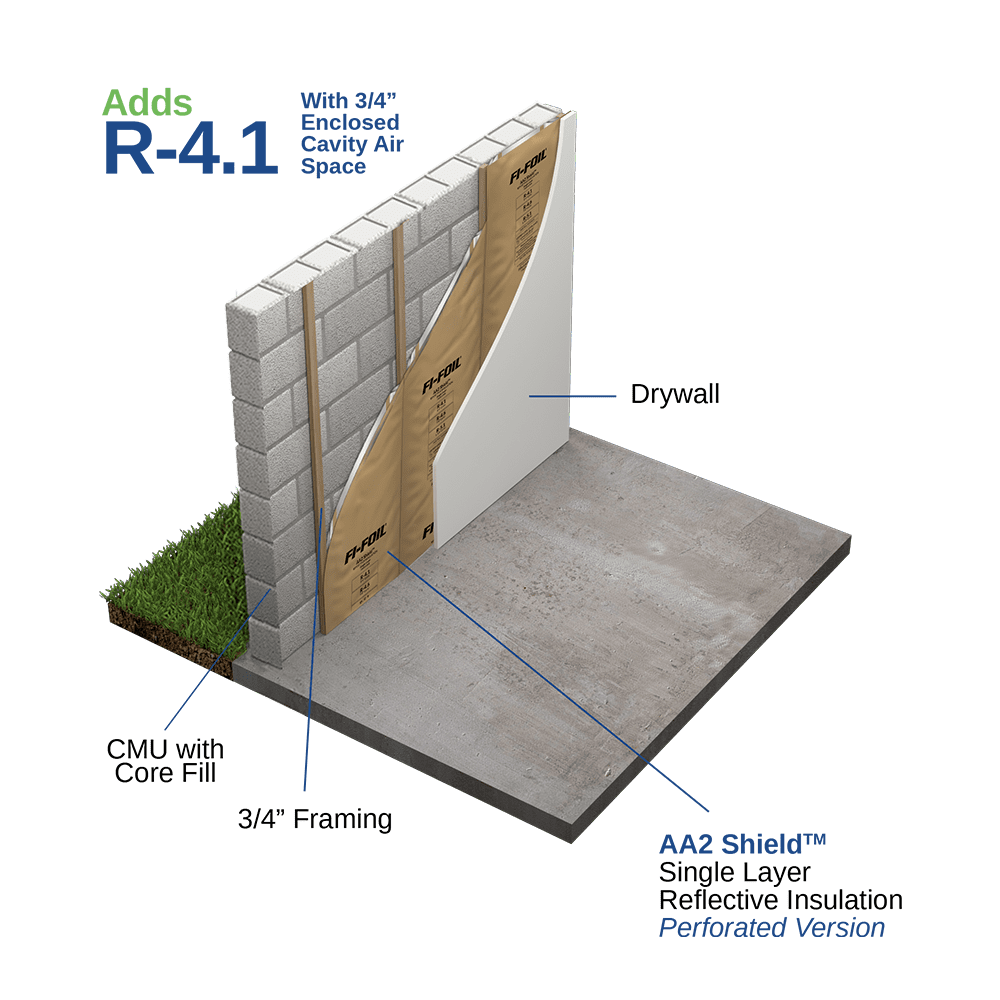

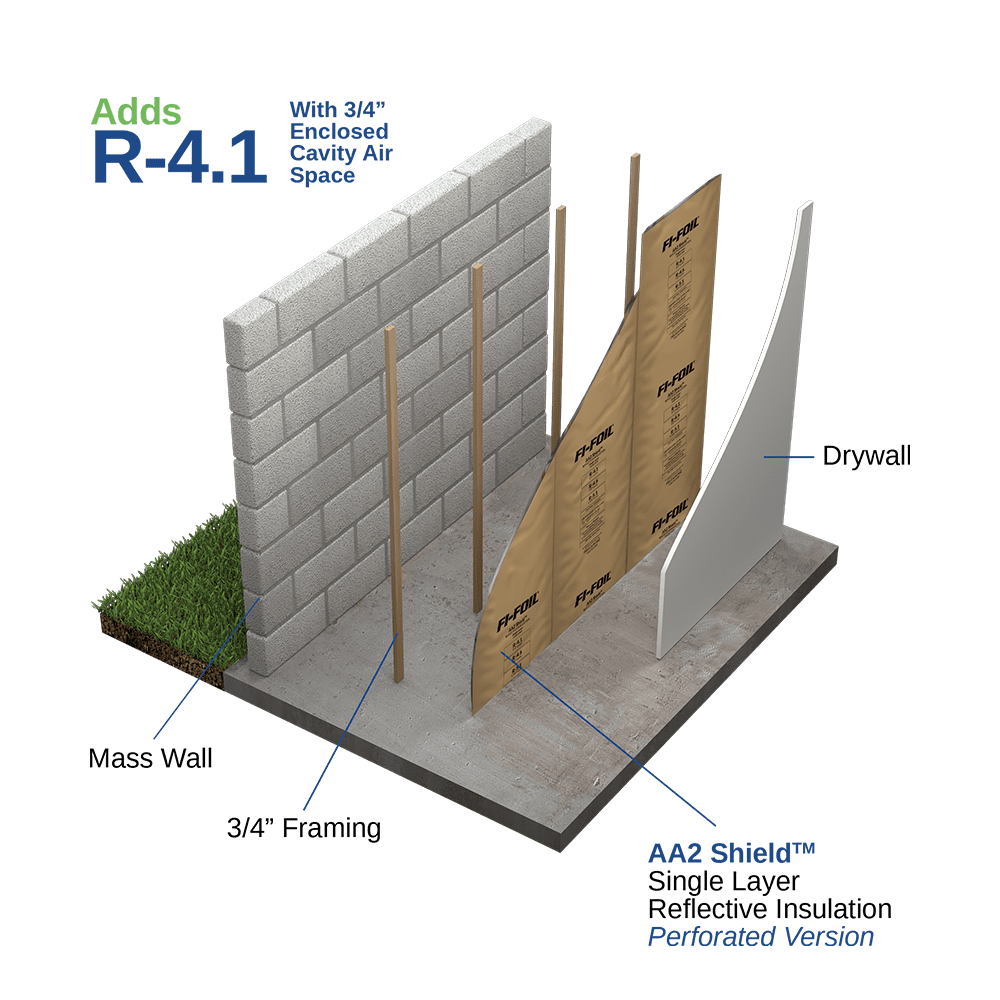

The Smart Insulation Choice for Masonry Walls

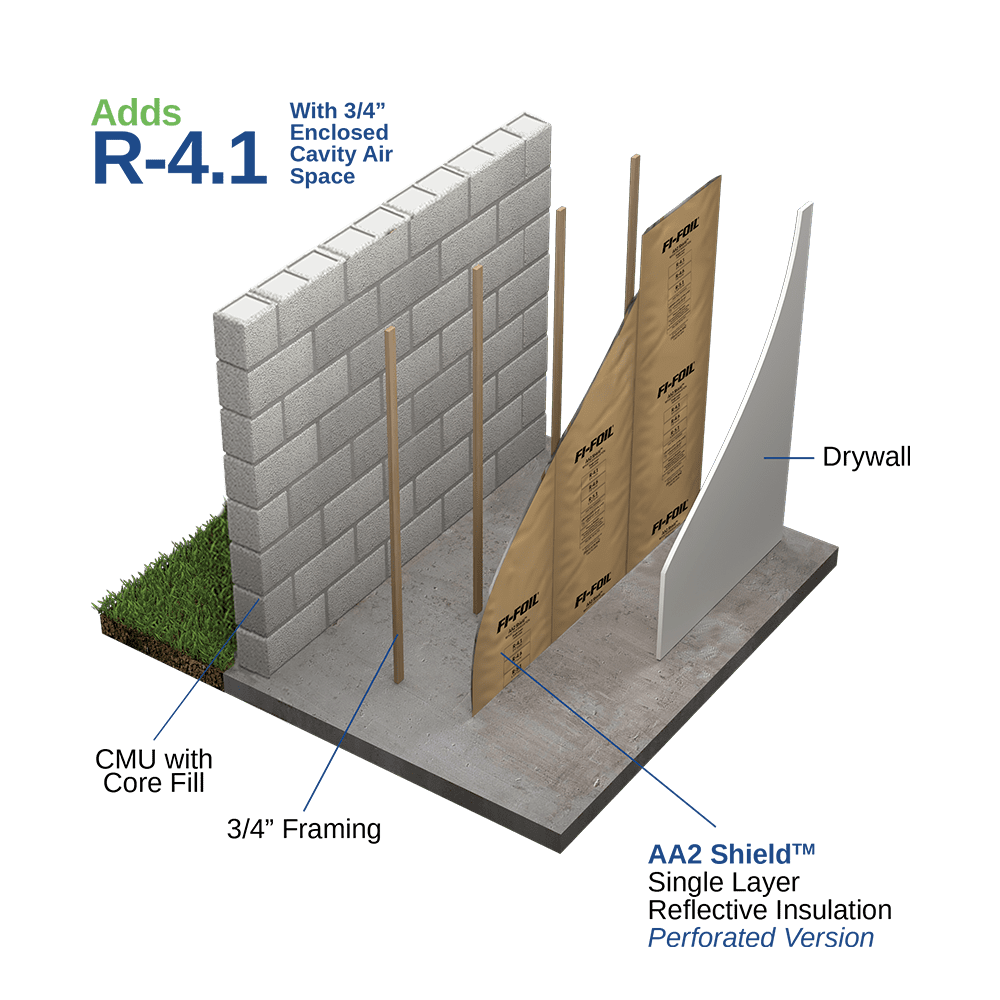

This insulation solution used on furred-out masonry walls, AA2 Shield™, is remarkably easy to install and effective in improving building performance and comfort. It’s designed to get you R-value for less, saving labor and material. Blocks 97% of heat transfer, plus an industry-leading 10-year transferrable warranty, AA2 Shield™ is a smart choice to insulate all your masonry buildings.

How It Works

We’ve blended high-grade aluminum foil with a tough yet natural layer of kraft paper with an extra polyethylene coating kick. It’s like a dynamic duo for your insulation needs.

Here is where our innovation kicks in. AA2 Shield™ employs expander technology to create a purposeful gap between the foil and paper. This separation sets the stage for reflective air pockets, significantly boosting the insulation’s effectiveness. When installed on furring strips at either 16″ or 24″ intervals, these air pockets perform at their peak, improving thermal properties and energy efficiency.

AA2 Shield™ also features a reflective component, which minimizes the air pocket sizes within the cavity. This contributes to reduced convective heat transfer, which gives your building an environment that’s more comfortable and excels in energy efficiency.

Features & Benefits That Make the Difference

- Two (2) Layer Reflective Air Spaces

- Outer Layer of Natural Kraft Paper

- Inner Layer of Premium Grade Aluminum Foil

- FI-FOIL® Expander Technology Separates Paper from Foil

- Low-e Surfaces to Block up to 97% Radiant Heat Transfer

- Quick Installation with Staple or Tape Tab

- Use with Wood Furring or Metal Framing

- 16″ or 24″ widths

- Perforated or Solid

- Lightweight 500 sq ft Rolls

- Easily Combine with Other Mass Insulation as part of a Wall System

- Verified Recycled Content >20%

- Supports Sustainable Design Goals

- Perforated Semi-Permeable Adds R-4.1 – R-5.1

- Solid Vapor Retarder Adds R-4.2 – R-5.2

- Easy to Handle, Installs Faster

- Save Labor

- Save Warehouse Space

- Save on Material & Shipping

- High Performance and Compact

- Provides for More Living Area Square-Footage for Increased Marketability

- Lowest Cost per R-value of All Masonry Wall Insulation

- Low-e Reflective Surfaces Improve Performance of Enclosed Air Space

- Lowers HERS® and Other Energy Rating Indexes (ERI)

- More Comfortable Buildings

- Better Energy Efficiency

- 10-Year Warranty

- Lifetime Limited Warranty

- National Network of Insulation Distributors and Contractors

Ensuring AA2 Shield™ Meets and Exceeds Industry Standards

- Meets or exceeds ASTM C1224, the Standard Specification of Reflective Insulation.

- Meets International Building, Residential and Energy Codes.

- Meets Florida Building, Residential and Energy Conversation Codes.

- IAPMO Evaluation Report number 0291.

- Meets ASTM C 1224, Reflective Insulation.

- Meets International Building Codes (IBC).

- Meets International Residential Codes (IRC).

- Meets International Energy Conservation Codes (IECC).

- Meets Florida Building Codes (FBC).

- Meets Florida Residential Codes (FRC).

- Meets Florida Energy Conservation Codes (FECC)

TECHNICAL DOCUMENTS

Request Product Support

Please don’t hesitate to reach out for inquiries, project consultations, or more information about FI-FOIL® reflective insulation system solutions. Our team of experts is dedicated to providing personalized assistance and technical expertise to meet your specific needs. Please note that the more completely the fields below are filled out, the more accurate your response will be.

A TRUSTED LEADER FOR REFLECTIVE INSULATION TECHNOLOGIES

PROVIDING YOU WITH SERVICE, INTEGRITY AND INNOVATION

We manufacture, market, and distribute high-performance reflective insulation technology and radiant barriers. Our products are sustainable and improve building performance and comfort all year round. Our reflective insulation technology is one of the fastest-growing technologies in the world and we want you to grow with us.

![AA2 Shield with Masonry Wall on Hat Channel [PDF] AA2 Shield™ with Masonry Wall on Hat Channel [PDF]](https://b3524466.smushcdn.com/3524466/wp-content/uploads/2024/02/AA2-Vapor-Shield-with-Masonry-Wall-on-Hat-Channel-PDF-pdf.jpg?lossy=2&strip=1&webp=1)

![AA2 Shield with Masonry Wall on Metal Framing [PDF] AA2 Shield™ with Masonry Wall on Metal Framing [PDF]](https://b3524466.smushcdn.com/3524466/wp-content/uploads/2024/02/AA2-Vapor-Shield-with-Masonry-Wall-on-Metal-Framing-PDF-pdf.jpg?lossy=2&strip=1&webp=1)

![AA2 Shield with Masonry Wall on Wood Furring [PDF] AA2 Shield™ with Masonry Wall on Wood Furring [PDF]](https://b3524466.smushcdn.com/3524466/wp-content/uploads/2024/02/AA2-Vapor-Shield-with-Masonry-Wall-on-Wood-Furring-PDF-pdf.jpg?lossy=2&strip=1&webp=1)

![Masonry Wall with M-Shield or AA2 Shield And Continuous Flex Foam Board Insulation Masonry Wall with M-Shield® or AA2 Shield™ and Continuous Flex Foam Board Insulation [PDF]](https://b3524466.smushcdn.com/3524466/wp-content/uploads/2024/02/Masonry-Wall-with-M-Shield-or-AA2-Vapor-Shield-And-Continuous-Flex-Foam-Board-Insulation-pdf.jpg?lossy=2&strip=1&webp=1)